Understanding RP Graphite Electrodes: Key Insights for the Metallurgical Industry

Release Time:

May 14,2025

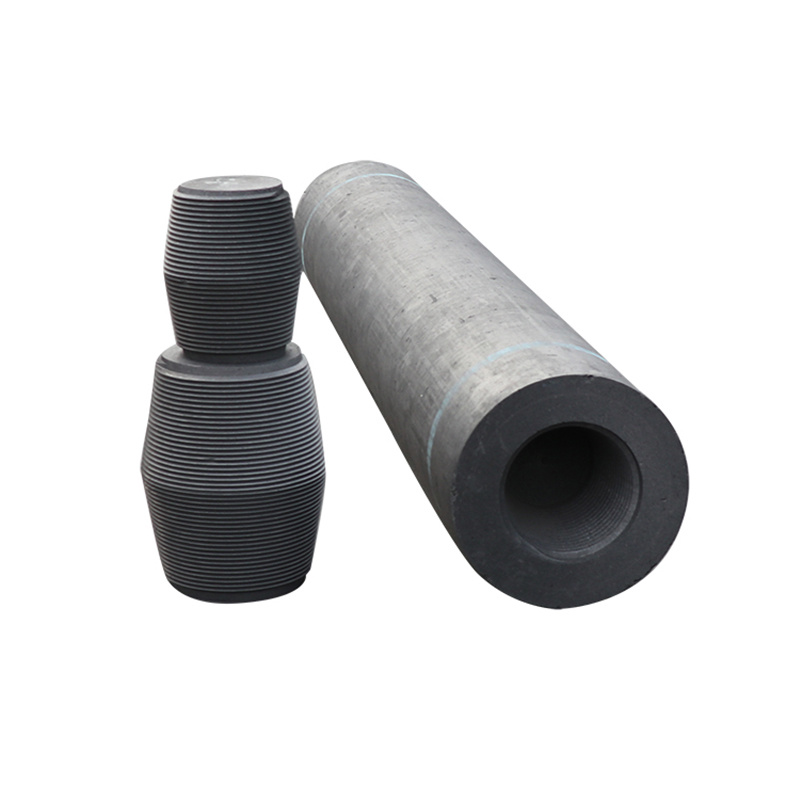

RP Graphite Electrodes are a crucial component in the metallurgical industry, particularly in electric arc furnaces (EAFs) for steelmaking and other metallurgical processes. These electrodes are made from petroleum or needle coke and are characterized by their excellent conductivity, high thermal resistance, and mechanical strength. Their unique properties make them suitable for various applicatio

RP Graphite Electrodes are a crucial component in the metallurgical industry, particularly in electric arc furnaces (EAFs) for steelmaking and other metallurgical processes. These electrodes are made from petroleum or needle coke and are characterized by their excellent conductivity, high thermal resistance, and mechanical strength. Their unique properties make them suitable for various applications in the non-metallic mineral sector, especially when it comes to high-temperature environments and electric arc operations.

One of the primary benefits of RP Graphite Electrodes is their ability to efficiently conduct electricity. This property is essential for electric arc furnaces, where high electric currents are necessary to melt scrap metal or other raw materials. The electrodes facilitate the generation of the intense heat required for these processes, which is crucial for achieving the desired metallurgical reactions. Additionally, their high thermal resistance ensures that they maintain structural integrity even under extreme conditions, minimizing the risk of breakage or wear during operation.

Another important aspect of RP Graphite Electrodes is their adaptability to various applications. They are not only used in steel production but also find applications in the production of ferroalloys, silicon metal, and other non-ferrous metals. Their versatility makes them an indispensable tool for manufacturers looking to optimize their production processes and improve the overall quality of their end products.

When choosing RP Graphite Electrodes, several factors should be considered, including the specific requirements of the application, the type of materials being processed, and the operating conditions of the furnace. The diameter and length of the electrodes can significantly impact their performance, and understanding the nuances of these specifications can lead to improved efficiency and reduced operational costs.

Moreover, using RP Graphite Electrodes can lead to significant advantages in terms of sustainability. The efficiency of electric arc furnaces powered by these electrodes contributes to a lower carbon footprint compared to traditional blast furnace methods. As industries increasingly focus on sustainability, the role of RP Graphite Electrodes becomes even more critical, providing a path toward greener metallurgical practices.

In conclusion, RP Graphite Electrodes play a vital role in the metallurgical industry, particularly within electric arc furnaces. Their electrical conductivity, thermal resistance, and adaptability to various applications make them an essential component for manufacturers. Understanding their properties and applications can help industries maximize efficiency and contribute to more sustainable practices in metal production. By focusing on the right specifications and suitable applications, businesses can leverage the benefits of RP Graphite Electrodes to enhance their operational capabilities and improve their overall production outcomes.

One of the primary benefits of RP Graphite Electrodes is their ability to efficiently conduct electricity. This property is essential for electric arc furnaces, where high electric currents are necessary to melt scrap metal or other raw materials. The electrodes facilitate the generation of the intense heat required for these processes, which is crucial for achieving the desired metallurgical reactions. Additionally, their high thermal resistance ensures that they maintain structural integrity even under extreme conditions, minimizing the risk of breakage or wear during operation.

Another important aspect of RP Graphite Electrodes is their adaptability to various applications. They are not only used in steel production but also find applications in the production of ferroalloys, silicon metal, and other non-ferrous metals. Their versatility makes them an indispensable tool for manufacturers looking to optimize their production processes and improve the overall quality of their end products.

When choosing RP Graphite Electrodes, several factors should be considered, including the specific requirements of the application, the type of materials being processed, and the operating conditions of the furnace. The diameter and length of the electrodes can significantly impact their performance, and understanding the nuances of these specifications can lead to improved efficiency and reduced operational costs.

Moreover, using RP Graphite Electrodes can lead to significant advantages in terms of sustainability. The efficiency of electric arc furnaces powered by these electrodes contributes to a lower carbon footprint compared to traditional blast furnace methods. As industries increasingly focus on sustainability, the role of RP Graphite Electrodes becomes even more critical, providing a path toward greener metallurgical practices.

In conclusion, RP Graphite Electrodes play a vital role in the metallurgical industry, particularly within electric arc furnaces. Their electrical conductivity, thermal resistance, and adaptability to various applications make them an essential component for manufacturers. Understanding their properties and applications can help industries maximize efficiency and contribute to more sustainable practices in metal production. By focusing on the right specifications and suitable applications, businesses can leverage the benefits of RP Graphite Electrodes to enhance their operational capabilities and improve their overall production outcomes.

Keywords:

More information