Exploring the Benefits of Using Graphite Electrodes in LF Applications

Release Time:

May 17,2025

Exploring the Benefits of Using Graphite Electrodes in LF Applications Table of Contents 1. Introduction to Graphite Electrodes 2. Understanding Ladle Furnace (LF) Applications 3. Benefits of Graphite Electrodes in LF Applications 3.1 High Electrical Conductivity 3.2 Superior Thermal Stability 3.3 Cost-Effectiveness 3.4 Environm

Exploring the Benefits of Using Graphite Electrodes in LF Applications

Table of Contents

- 1. Introduction to Graphite Electrodes

- 2. Understanding Ladle Furnace (LF) Applications

- 3. Benefits of Graphite Electrodes in LF Applications

- 3.1 High Electrical Conductivity

- 3.2 Superior Thermal Stability

- 3.3 Cost-Effectiveness

- 3.4 Environmental Benefits

- 4. Practical Applications of Graphite Electrodes

- 5. Challenges in Using Graphite Electrodes

- 6. Future Trends in Graphite Electrode Usage

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Graphite Electrodes

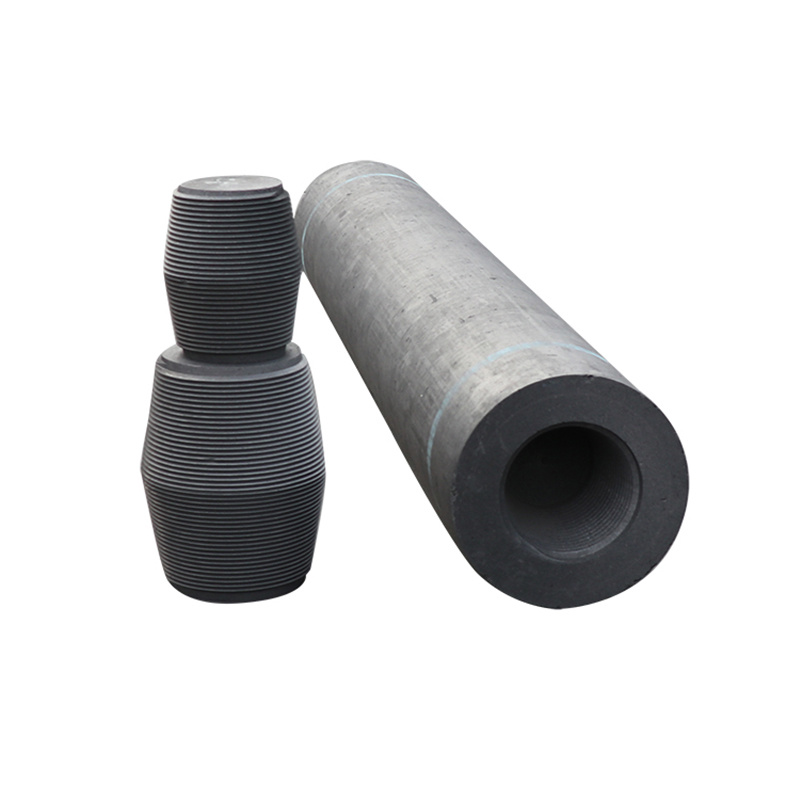

Graphite electrodes play a critical role in the metallurgical industry, particularly in the steel production process. These electrodes are primarily made from high-quality petroleum or needle cokes, which are then subjected to high temperatures in a process called graphitization. The result is a highly conductive material that is vital for electric arc furnaces (EAF) and ladle furnaces (LF). Understanding the **benefits of using graphite electrodes in LF applications** can lead to improved efficiency in steel production, enhanced product quality, and lower operational costs.

2. Understanding Ladle Furnace (LF) Applications

Ladle furnaces are essential components of modern steelmaking processes. They are utilized for refining molten steel before it is cast into slabs, billets, or blooms. The primary purpose of LF is to adjust the temperature and composition of the steel, ensuring that it meets specific requirements for various applications. In this context, graphite electrodes are indispensable, as they facilitate the heating and stirring of the molten metal while allowing for precise control over the steel’s chemical composition.

3. Benefits of Graphite Electrodes in LF Applications

3.1 High Electrical Conductivity

One of the most significant advantages of graphite electrodes is their **high electrical conductivity**. This property allows for efficient energy transfer during the steel refining process. By providing a low-resistance path for electric current, graphite electrodes enable the LF to reach the desired temperature quickly and effectively. This efficiency not only reduces energy consumption but also enhances the overall productivity of the steelmaking process.

3.2 Superior Thermal Stability

In LF applications, maintaining a consistent temperature is crucial. Graphite electrodes exhibit **superior thermal stability**, allowing them to withstand the extreme conditions inside the furnace without degrading. This durability leads to longer electrode life and reduced replacement costs, which are significant factors in optimizing the operation of ladle furnaces.

3.3 Cost-Effectiveness

Using graphite electrodes in LF applications also translates to **cost-effectiveness**. While the initial investment in high-quality graphite electrodes may be higher than other materials, their longevity and reduced maintenance needs ultimately lead to lower operational costs. Additionally, the efficient performance of these electrodes minimizes energy consumption, further contributing to cost savings for steel producers.

3.4 Environmental Benefits

As industries worldwide shift towards more sustainable practices, the use of graphite electrodes presents notable **environmental benefits**. By enhancing the efficiency of the steelmaking process, these electrodes help to reduce greenhouse gas emissions associated with energy consumption. Furthermore, the use of recycled materials in the production of graphite electrodes supports a more circular economy, aligning with global sustainability goals.

4. Practical Applications of Graphite Electrodes

Graphite electrodes are versatile and can be tailored for various LF applications. Their use extends beyond steelmaking to include:

- **Foundry Applications**: Graphite electrodes help in melting and refining metal alloys, providing high-quality castings.

- **Non-Ferrous Metal Production**: They are used in the production of metals such as aluminum and copper, facilitating the required temperatures for melting and refining.

- **Electrochemical Processes**: Graphite electrodes are critical in electrolysis, battery manufacturing, and other electrochemical applications, showcasing their adaptability across industries.

5. Challenges in Using Graphite Electrodes

Despite their numerous advantages, there are challenges associated with using graphite electrodes in LF applications. These include:

- **Cost Fluctuations**: The prices of raw materials used in graphite electrode production can be volatile, impacting overall costs.

- **Technical Limitations**: Some applications may require electrodes with specific properties that standard graphite electrodes may not meet, necessitating custom solutions.

- **Environmental Concerns**: While graphite electrodes are beneficial, the production process can generate emissions, requiring manufacturers to adopt cleaner technologies.

6. Future Trends in Graphite Electrode Usage

As the steel industry evolves, the future of graphite electrodes appears promising. Emerging trends include:

- **Enhanced Manufacturing Techniques**: Innovations in production processes aim to improve the quality and performance of graphite electrodes, potentially leading to new application areas.

- **Sustainability Initiatives**: Increased focus on sustainability will drive the development of environmentally friendly electrode materials and production methods.

- **Smart Technology Integration**: The incorporation of smart technologies and automation in steelmaking processes is expected to further enhance the efficiency and effectiveness of graphite electrodes in LF applications.

7. Frequently Asked Questions

1. What materials are graphite electrodes made from?

Graphite electrodes are primarily made from high-quality petroleum or needle cokes, which undergo a process called graphitization to enhance their electrical and thermal properties.

2. How do graphite electrodes improve steel quality?

Graphite electrodes provide precise control over the temperature and chemical composition of molten steel, resulting in enhanced quality and consistency of the final product.

3. Are graphite electrodes eco-friendly?

Yes, the use of graphite electrodes can lead to reduced energy consumption and lower greenhouse gas emissions, contributing to a more sustainable steelmaking process.

4. What are the typical applications of graphite electrodes?

Graphite electrodes are commonly used in steel production, foundry applications, non-ferrous metal production, and electrochemical processes.

5. What challenges do manufacturers face with graphite electrodes?

Manufacturers may encounter challenges such as cost fluctuations in raw materials, technical limitations for specific applications, and environmental concerns associated with production processes.

8. Conclusion

In summary, the **benefits of using graphite electrodes in LF applications** are significant, ranging from high electrical conductivity and thermal stability to cost-effectiveness and environmental advantages. As the steel industry continues to evolve, the role of graphite electrodes will remain pivotal in enhancing production efficiency and sustainability. By understanding these benefits and the challenges involved, manufacturers can make informed decisions that will ultimately lead to improved outcomes in steelmaking and beyond. Embracing the innovative potential of graphite electrodes paves the way for a more efficient and environmentally friendly future in metallurgy.

Keywords:

More information