Understanding High Power Graphite Electrodes and Their Applications in Metallurgy

Release Time:

May 26,2025

High power graphite electrodes are essential components in the metallurgy sector, particularly in the production of steel and other metals. These electrodes are designed to withstand high temperatures and carry large electric currents, making them ideal for electric arc furnaces (EAFs). The unique properties of high power graphite electrodes, including their excellent thermal conductivity and resi

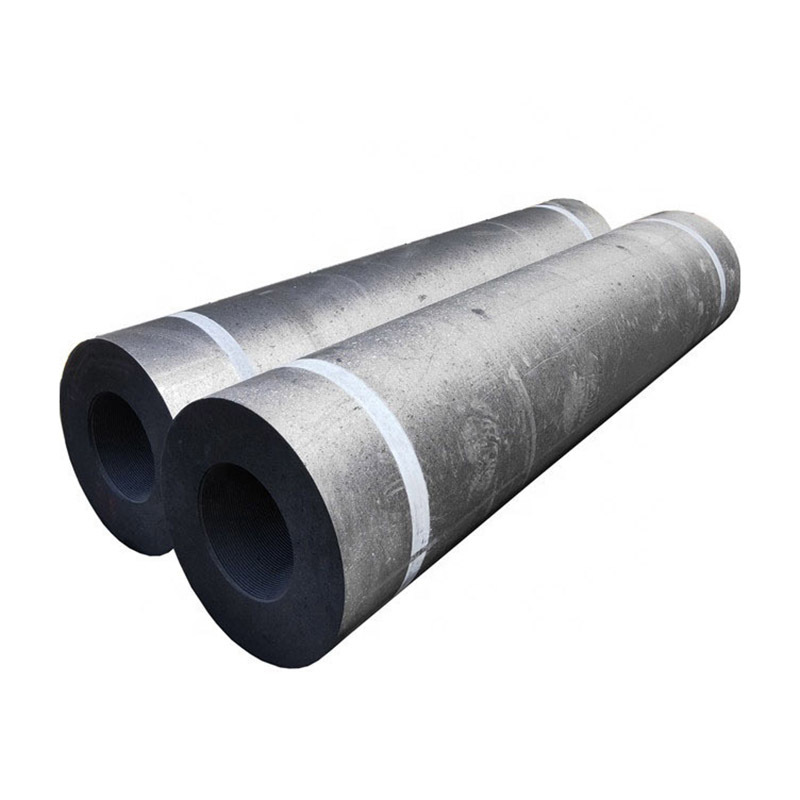

High power graphite electrodes are essential components in the metallurgy sector, particularly in the production of steel and other metals. These electrodes are designed to withstand high temperatures and carry large electric currents, making them ideal for electric arc furnaces (EAFs). The unique properties of high power graphite electrodes, including their excellent thermal conductivity and resistance to thermal shock, enable them to perform efficiently in demanding environments.

One of the primary advantages of high power graphite electrodes is their ability to facilitate the melting of scrap metal in EAFs. The high temperatures generated by the electric arc allow for effective and efficient melting, which is crucial for recycling operations. Additionally, high power graphite electrodes have a lower resistivity compared to standard electrodes, resulting in reduced energy consumption during the melting process. This efficiency not only lowers operational costs but also minimizes the carbon footprint associated with metal production.

The manufacturing process of high power graphite electrodes involves the use of high-quality petroleum needle coke as a raw material. This material is subjected to high-temperature treatment, which enhances its graphitic structure. The resulting electrodes exhibit high density and low expansion, making them suitable for high-power applications. Moreover, their mechanical strength ensures durability and longevity, reducing the frequency of replacements and enhancing productivity in metallurgical operations.

In addition to steel production, high power graphite electrodes are also utilized in the production of non-ferrous metals, such as aluminum and copper. Their ability to withstand extreme conditions makes them versatile tools in various metallurgical processes. Furthermore, these electrodes can be customized in terms of size and shape to meet specific operational requirements, further broadening their applicability in different industries.

The demand for high power graphite electrodes continues to rise as industries strive for more efficient and environmentally friendly production methods. As metallurgical operations evolve, the development of advanced materials and technologies is essential. High power graphite electrodes are at the forefront of this evolution, providing a reliable solution for energy-intensive processes.

In conclusion, high power graphite electrodes play a pivotal role in the metallurgy sector, offering exceptional performance in electric arc furnaces and other applications. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable in modern metal production. By leveraging these electrodes, industries can achieve greater efficiency, sustainability, and overall productivity. Understanding the significance of high power graphite electrodes is crucial for any entity looking to optimize their metallurgical processes and stay competitive in the market.

One of the primary advantages of high power graphite electrodes is their ability to facilitate the melting of scrap metal in EAFs. The high temperatures generated by the electric arc allow for effective and efficient melting, which is crucial for recycling operations. Additionally, high power graphite electrodes have a lower resistivity compared to standard electrodes, resulting in reduced energy consumption during the melting process. This efficiency not only lowers operational costs but also minimizes the carbon footprint associated with metal production.

The manufacturing process of high power graphite electrodes involves the use of high-quality petroleum needle coke as a raw material. This material is subjected to high-temperature treatment, which enhances its graphitic structure. The resulting electrodes exhibit high density and low expansion, making them suitable for high-power applications. Moreover, their mechanical strength ensures durability and longevity, reducing the frequency of replacements and enhancing productivity in metallurgical operations.

In addition to steel production, high power graphite electrodes are also utilized in the production of non-ferrous metals, such as aluminum and copper. Their ability to withstand extreme conditions makes them versatile tools in various metallurgical processes. Furthermore, these electrodes can be customized in terms of size and shape to meet specific operational requirements, further broadening their applicability in different industries.

The demand for high power graphite electrodes continues to rise as industries strive for more efficient and environmentally friendly production methods. As metallurgical operations evolve, the development of advanced materials and technologies is essential. High power graphite electrodes are at the forefront of this evolution, providing a reliable solution for energy-intensive processes.

In conclusion, high power graphite electrodes play a pivotal role in the metallurgy sector, offering exceptional performance in electric arc furnaces and other applications. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable in modern metal production. By leveraging these electrodes, industries can achieve greater efficiency, sustainability, and overall productivity. Understanding the significance of high power graphite electrodes is crucial for any entity looking to optimize their metallurgical processes and stay competitive in the market.

Keywords:

More information