From Production to Application: The Journey of Regular Power Graphite Electrodes

Release Time:

May 29,2025

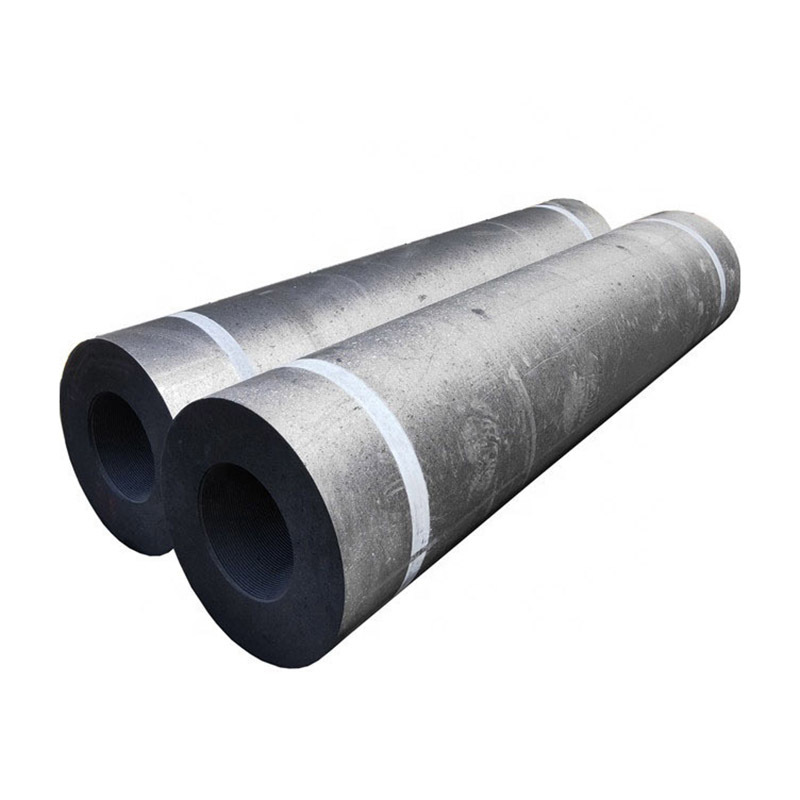

From Production to Application: The Journey of Regular Power Graphite Electrodes In today's industrial landscape, the demand for efficient materials is paramount, particularly in sectors that require high thermal and electrical conductivity. Among such materials, **regular power graphite electrodes** stand out as vital components in the manufacturing of steel and other metals. This article will ta

From Production to Application: The Journey of Regular Power Graphite Electrodes

In today's industrial landscape, the demand for efficient materials is paramount, particularly in sectors that require high thermal and electrical conductivity. Among such materials, **regular power graphite electrodes** stand out as vital components in the manufacturing of steel and other metals. This article will take you on a thorough exploration of the journey of regular power graphite electrodes, detailing their production process, properties, applications, and future trends.

Table of Contents

- 1. Introduction to Regular Power Graphite Electrodes

- 2. The Manufacturing Process of Graphite Electrodes

- 2.1 Raw Materials Used in Production

- 2.2 Baking and Graphitization Process

- 2.3 Machining and Finishing Steps

- 3. Key Properties of Regular Power Graphite Electrodes

- 4. Applications of Regular Power Graphite Electrodes

- 5. Future Trends in Graphite Electrode Technology

- 6. Conclusion

- 7. Frequently Asked Questions

1. Introduction to Regular Power Graphite Electrodes

Regular power graphite electrodes are essential components in electric arc furnaces (EAFs), primarily used for steel production. Their ability to conduct electricity efficiently while withstanding high temperatures makes them an ideal choice for various heating applications in industrial processes. Understanding the journey of these electrodes, from their creation to their applications, is crucial for industries that rely heavily on metal production and processing.

2. The Manufacturing Process of Graphite Electrodes

The production of regular power graphite electrodes involves a series of meticulous processes that transform raw materials into high-quality electrodes. Let’s break down the key stages of this manufacturing journey.

2.1 Raw Materials Used in Production

The primary raw materials for manufacturing graphite electrodes include **petroleum coke**, **pitch**, and other carbon-based materials. Petroleum coke is derived from the oil refining process and serves as the main carbon source. The quality and properties of the final graphite product are significantly influenced by the selection of these raw materials, making them pivotal to the manufacturing process.

2.2 Baking and Graphitization Process

After preparing the raw materials, the next step is the **baking process**, where the petroleum coke and pitch are heated in a controlled environment. This heating converts the materials into a solid carbon structure. Following baking, the electrodes undergo **graphitization**, a critical step where they are heated to extremely high temperatures (around 3000°C) in an inert atmosphere. This process not only increases the electrical conductivity of the electrodes but also enhances their thermal properties.

2.3 Machining and Finishing Steps

Once graphitization is complete, the electrodes are subjected to precise **machining** to achieve the desired dimensions and surface finish. This stage often involves cutting, milling, and drilling operations. The electrodes are then inspected for quality assurance, ensuring they meet the necessary industry standards before they are packaged and shipped to clients.

3. Key Properties of Regular Power Graphite Electrodes

The effectiveness of regular power graphite electrodes in industrial applications can be attributed to their unique properties:

- Electrical Conductivity: Graphite is one of the best conductors of electricity, which is critical in applications involving electric arc furnaces.

- Thermal Stability: These electrodes can withstand high temperatures without significant degradation, making them ideal for steel production.

- Low Thermal Expansion: Graphite has a low coefficient of thermal expansion, reducing the risk of thermal shock during rapid heating and cooling cycles.

- Chemical Resistance: Graphite electrodes are resistant to many chemicals and can operate in harsh environments, enhancing their durability.

4. Applications of Regular Power Graphite Electrodes

The versatility of regular power graphite electrodes allows them to be utilized in a range of applications across various industries.

4.1 Role in Steel Making

The primary application of regular power graphite electrodes is in the **steel-making industry**. They are crucial in electric arc furnaces where scrap steel is melted down. Their ability to conduct electricity efficiently and maintain structural integrity at high temperatures makes them indispensable in this process. As steel production continues to grow globally, the demand for high-quality graphite electrodes is expected to rise.

4.2 Applications in Other Industries

Apart from steelmaking, regular power graphite electrodes find their application in various other sectors, including:

- Aluminum Production: Used in the production of aluminum smelting processes.

- Foundries: Employed in casting and molding processes.

- Chemical Industries: Utilized in electrochemical processes due to their chemical resistance.

- Battery Manufacturing: Serve as conductive materials in lithium-ion batteries, contributing to energy storage solutions.

5. Future Trends in Graphite Electrode Technology

As industries evolve, so does the technology surrounding graphite electrodes. Some notable future trends include:

- Sustainable Production: With the growing emphasis on sustainability, manufacturers are exploring eco-friendly methods of graphite production.

- Advanced Materials: Research is ongoing to develop composite materials that enhance the efficiency and performance of graphite electrodes.

- Recycling Solutions: Effective recycling methods for used electrodes are being researched to reduce waste and promote circular economy practices.

6. Conclusion

The journey of regular power graphite electrodes from production to application is a testament to their crucial role in various industrial processes. As we have explored, their manufacturing involves intricate processes that ensure high-quality output, and their unique properties make them indispensable in sectors like steel production and beyond. As the industry moves toward sustainability and innovation, the future of graphite electrodes looks promising, paving the way for further advancements in technology and material science.

7. Frequently Asked Questions

What are regular power graphite electrodes used for?

Regular power graphite electrodes are primarily used in electric arc furnaces for steel production and play a role in various other industries, including aluminum production and chemical manufacturing.

How are graphite electrodes produced?

The production process includes sourcing raw materials, baking, graphitization, and machining to achieve the desired dimensions and properties.

What properties make graphite electrodes ideal for industrial applications?

Graphite electrodes are characterized by high electrical conductivity, thermal stability, low thermal expansion, and chemical resistance, making them suitable for high-temperature applications.

Are there any environmental concerns related to graphite electrode production?

Yes, there are environmental concerns, particularly regarding the sourcing of raw materials and waste generation. The industry is exploring sustainable practices to mitigate these impacts.

What is the future of graphite electrodes in technology?

The future includes advancements in sustainable production, the development of composite materials, and improved recycling methods to enhance efficiency and reduce environmental impact.

Keywords:

More information